Composite Prepregs

Axiom announces new website launch Jun 3rd

Axiom Materials formulates and manufactures prepreg utilizing resin systems including epoxy, phenolic, polyester, cyanate ester, polyimide and bismaleimide. Todays demanding operational environments require manufacturers have options for performance materials that meet their needs whether it is at -70°F to 900°F.

Download The Axiom Product Guide

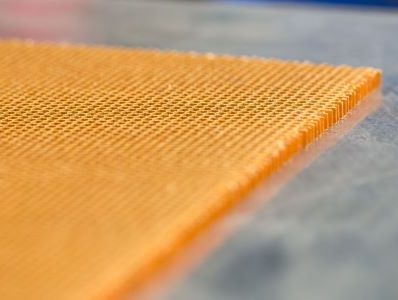

From toughened epoxy to fire retardant products, Axiom has been formulating and manufacturing advanced prepregs for almost every composite structure from the deep sea to deep space. Our prepregs are available in formats utilizing woven and stitched reinforcements as well as unidirectional. Options for off the shelf prepregs as well as customizable formats in width, length, tack and color are all available. Consult with one of our seasoned team members to discuss your needs.

Speak To A Materials Expert

Processing – Axiom Materials prepregs are formulated for processing in autoclave, press and out of autoclave (vacuum bag / oven). Our products are tailored so that they can be cured at low at 170F and as high as 350F with higher post-cures as needed.

Flexibility – Axiom Materials prepregs can are made to be flexible in the tack, drapability, resin content, color, flow and volatiles. These prepregs are manufactured in both hot melt and solution coated tower processes.

If you have any questions about out Composite Prepregs product line please let us know. We are readily available to discuss you application, learn more about your needs, and address any questions.

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-3100 | Toughened Low Dielectric Epoxy Fiberglass Prepreg | High transmission applications, radomes | Woven Prepreg, solution coated | Off-white on white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853 |

| AX-3110 | Toughened, Flame Retardant Epoxy Fiberglass Prepreg | Flame retardant laminates, honeycomb and foam panels | Woven Prepreg (1 or 2-side coated) | Off-white on white | 250°F (121°C) | 180°F (82°C) | Meets FAR 25.853 |

| AX-3112T | High Toughness Flame Retardant Epoxy Fiberglass Prepreg | High toughness, flame retardant laminates, ducting, honeycomb panels, and foam panels | Woven Prepreg, solution coated | Off-white on white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853. High Temp (HT) grade available |

| AX-3170 | Cyanate Ester Fiberglass Prepreg | High service temperature laminates with low dielectric constant & low dissipation factor | Woven Prepreg (1 or 2-side coated) | Clear on white | 260°F (127°C) | 700°F (371°C) | 700°F service achieved using 550°F post cure |

| AX-3180 | Low OSU /FST Epoxy Fiberglass Prepreg | Aircraft interior laminates & panels, A/C ducting | Woven Prepreg (1 or 2-side coated) | White on white | 250°F (121°C) | 250°F (121°C) | Meets 25.853 & FST / OSU. Snap Cure (SC) available. |

| AX-3201XL | Toughened Epoxy Fiberglass Laminating Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | Woven Prepreg (1 or 2-side coated) | Clear on white | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available. |

| AX-3206 | Toughened Epoxy Fiberglass Laminating Prepreg | High toughness laminates for prosthetics and race car industry | Woven Prepreg (1 or 2-side coated) | White on white | Variable | 250°F (121°C) | More toughened than AX-3201 series. |

| AX-3220 | High Temperature Epoxy Fiberglass Prepreg | High temperature laminates and high temperature ducting | Woven Prepreg (1 or 2-side coated) | Clear on white | 350°F (177°C) | 400°F (204°C) | Post cure recommended for peak performance. FR grade available. |

| AX-3260EL | Epoxy Fiberglass Tooling Prepreg | Low temperature cure, high temperature service tooling | Woven Prepreg (1 or 2-side coated) | Light amber on white | 125°F (52°C) initial, 380°F (193°C) final | 375°F (191°C) | Low temperature initial cure, then free-standing post cure to achieve Tg |

| AX-3270 | Structural Epoxy Fiberglass Prepreg | Structural composite components | Woven Prepreg (1 or 2-side coated) | Cream on white | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-4110 | Toughened, Flame Retardant Epoxy Aramid Prepreg | Flame retardant laminates, honeycomb panels, and foam panels | Woven Prepreg (1 or 2-side coated) | Off-white on yellow | 250°F (121°C) | 180°F (82°C) | Meets FAR 25.853 |

| AX-4112T | High Performance, Toughened Epoxy Aramid Prepreg | High toughness, FR laminates, ducting, honeycomb panels, and foam panels | Woven Prepreg, solution coated | Off-white on yellow | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853 |

| AX-4151 | Modified PVB Phenolic Aramid Prepreg | High strength and impact-resistant bonding and laminating typically for ballistic applications | Woven Prepreg (1 or 2-side coated) | Off-white on yellow | 275°F (135°C) | 180°F (82°C) | Resin meets MIL-DTL-62474F |

| AX-4180 | Low OSU / FST Epoxy Aramid Prepreg | Aircraft interior laminates & panels, A/C ducting | Woven Prepreg (1or 2-side coated) | White on yellow | 250°F (121°C) | 250°F (121°C) | Meets FAR 25.853 & FST / OSU requirements |

| AX-4201XL | Toughened Epoxy Aramid Laminating Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | Woven Prepreg (1 or 2-side coated) | Clear on yellow | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available |

| AX-4220 | High Temperature Epoxy Laminating Aramid Prepreg | High temperature laminates and high temperature ducting | Woven Prepreg (1 or 2-side coated) | Clear on yellow | 350°F (177°C) | 400°F (204°C) | Post cure recommended for peak performance. FR grade available. |

| AX-4270 | Structural Epoxy Aramid Prepreg | Structural composite components | Woven Prepreg (1 or 2-side coated) | Cream on yellow | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

| AX-4300 | High Temperature Phenolic Laminating Aramid Prepreg | Ballistic panels, high temperature laminates | Woven Prepreg, solution coated | Amber on yellow | 300°F (149°C) | 500°F (260°C) | Resin meets MIL-R-9299C |

| AX-4500 | Toughened Phenolic Aramid Prepreg, Self-Adhesive | Honeycomb panels for aircraft interior components | Woven Prepreg, solution coated | Amber on yellow | 275°F (135°C) | 250°F (121°C) | Press grade and layup grade available |

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-5112T | High Toughness, Flame Retardant Epoxy Carbon Prepreg | High toughness, flame retardant laminates, ducting, & honeycomb panels | Woven Prepreg, solution coated | Off-white on black | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853 |

| AX-5170 | Cyanate Ester Carbon Prepreg | High service temperature laminates | Woven Prepreg (1 or 2-side coated) | Clear on black | 260°F (127°C) | 700°F (371°C) | 700°F service achieved using 550°F post cure |

| AX-5180 | Low OSU / FST Epoxy Carbon Prepreg | Aircraft interior laminates & panels, A/C ducting | Woven Prepreg (1 or 2-side coated) | White on black | 250°F (121°C) | 250°F (121°C) | Meets FAR 25.853 & FST / OSU requirements. Color variations available. |

| AX-5201XL | Toughened Epoxy Carbon Laminating Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | Woven Prepreg (1 or 2-side coated) | Clear or black on black | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available |

| AX-5202HT | High Temp Cosmetic Epoxy Carbon Prepreg | UV resistant parts requiring high thermal resistance | Woven Prepreg (1 or 2-side coated) | Clear on black | Variable | 425°F (218°C) | Used extensively in autosport applications |

| AX-5205 | Epoxy Carbon Prepreg for High Quality Surface | Low temp or standard temp option for laminates requiring a high quality surface and cosmetic appearance | Woven Prepreg (1 or 2-side coated) | Clear or black on black | Variable | 250°F (121°C) | Low temp cure grade available (S) |

| AX-5206 | Toughened Epoxy Carbon Laminating Prepreg | High toughness laminates for prosthetics and race car industry | Woven Prepreg (1 or 2-side coated) | White or black on black | Variable | 250°F (121°C) | More toughened than AX-5201 series |

| AX-5209 | High Quality Surface Epoxy Carbon Prepreg | High clarity, low void content laminates requiring low temperature initial cure | Woven Prepreg (1 or 2-side coated) | Clear on black | 150°F (66°C) initial, 210°F (99°C) final | 250°F (121°C) | Low temperature initial cure, then free-standing post cure to achieve Tg |

| AX-5220 | High Temperature Epoxy Laminating Carbon Prepreg | High temperature laminates, high temperature ducting | Woven Prepreg (1 or 2-side coated) | Clear on black | 350°F (177°C) | 400°F (204°C) | Post cure recommended for peak performance. FR grade available. |

| AX-5260EL | Epoxy Carbon Tooling Prepreg | Low temperature cure, high temperature service tooling | Woven Prepreg (1 or 2-side coated) | Black on black | 125°F (52°C) initial, 380°F (193°C) final | 375°F (191°C) | Low temperature initial cure, then free-standing post cure to achieve Tg |

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-6111 | General Purpose Flame Retardant Epoxy Unidirectional Prepreg | Aircraft flooring, high-rise flooring, cargo liners, high impact surfaces, UAVs, sporting goods | UD prepreg (2-side coated) | Off-white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853. |

| AX-6180 | Low FST/OSU Epoxy Unidirectional Prepreg | Aircraft interior components, seatbacks, doublers | UD prepreg (2-side coated) | White | 250°F (121°C) | 250°F (121°C) | Meets FAR 25.853 & FST / OSU requirements |

| AX-6200 | Toughened, High Clarity Epoxy Unidirectional Prepreg | Performance sporting goods, automotive parts & components | UD prepreg (2-side coated) | Clear or light black | 250°F (121°C) | 250°F (121°C) | General purpose |

| AX-6201XL | Toughened Epoxy Unidirectional Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | UD prepreg (2-side coated) | Clear or light black | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available |

| AX-6270 | Structural Epoxy Unidirectional Prepreg | Structural composite components | UD prepreg (2-side coated) | Cream | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

"*" indicates required fields

CMC prepregs are used for parts requiring thermal performance up to 2200°F

Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.